Highly Efficient Automation

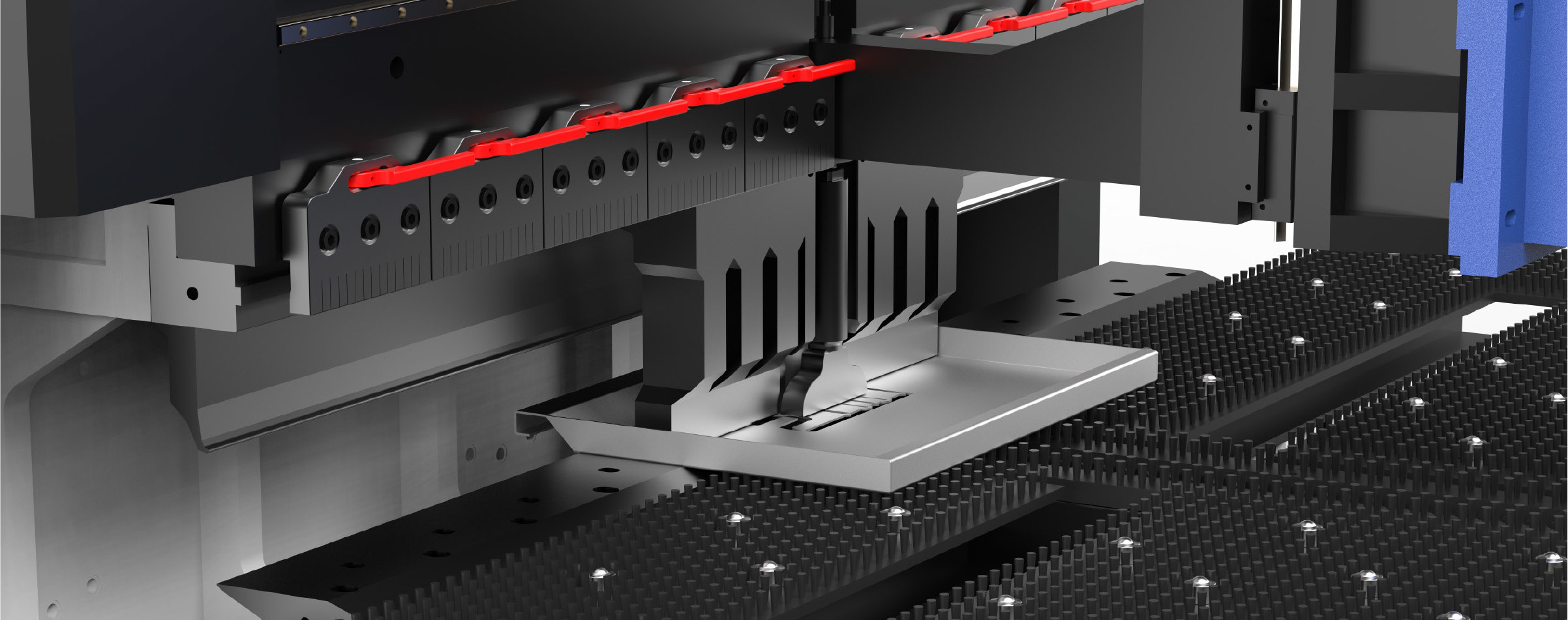

By adopting servo electric technology and multi-axis linkage control, the machine achieves a fastest bending speed of just 0.2 seconds per stroke, representing a 260% efficiency improvement over conventional equipment. Optional features include automatic material feeding and automated bending, minimizing manual intervention. This allows the machine to seamlessly perform complex operations such as four-sided bends and arc bends, enabling efficient mass production.

ZYE series

Flexible Bending Center

Classification:

Press Brake

Graphic details

Video Introduction

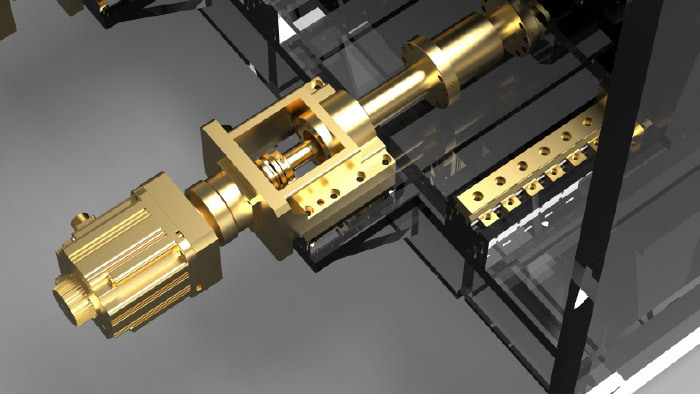

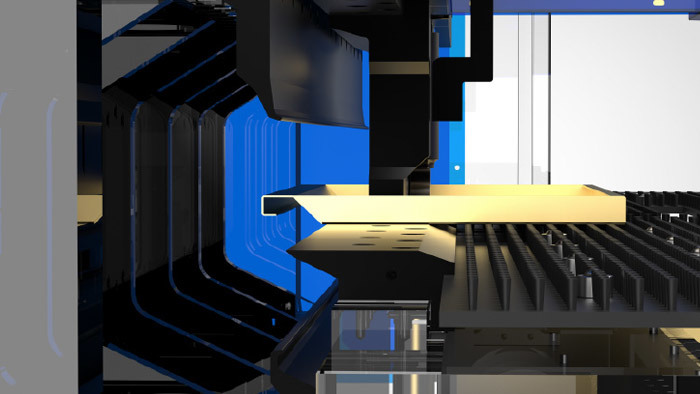

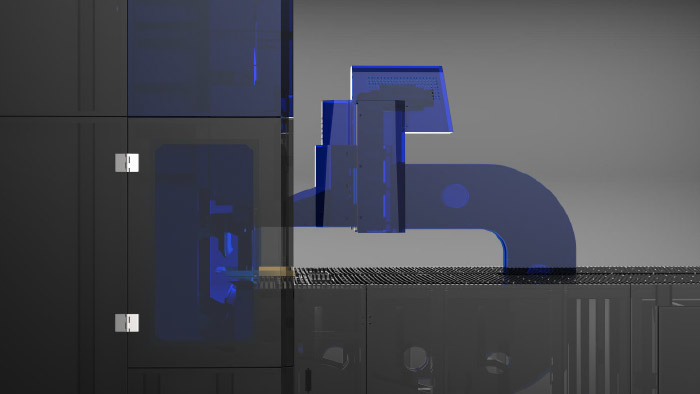

Introduction to the Standard Configuration

High Precision and Flexibility

Equipped with high-precision sensors and a CNC system, this machine achieves repeat positioning accuracy as low as 0.01mm, with minimal angular error, ensuring consistent workpiece quality. There’s no need for frequent mold changes—simply adjust the program to accommodate various shapes (such as dead-edge pressing, return-type, or closed-type designs) and material requirements.

Technical Specifications

| Shipping Structure | Arm-pressing type | |

| System minimum precision | 0.001mm | |

| Fastest bending speed | 0.2 seconds per cut | |

| Maximum Feed Rate | 90m/min | |

| Maximum bending width | 1500mm | Customizable according to customer workpieces |

| Maximum Bending Dimension | 1500mm × 1500mm | |

| Maximum bending height | 180mm | |

| Minimum bending height | 4mm | Proportional to the bending plate thickness |

| Minimum arc radius | 0.5mm | |

| Rated Voltage | 380V | |

| Total motor power | 41KW | |

| Noise | About 50 decibels | |

| External dimensions | 4800mm × 2300mm × 2950mm | |

| Total mass | Approximately 15 tons | |

| Maximum Bending Thickness | 304 Stainless Steel, 1.5mm | |

| Cold Plate 2.0mm | ||

| Minimum material thickness | 0.35mm | |

| Workpiece diffraction size | 40mm | Customizable according to customer workpieces |

| Bilateral forming minimum size | 140mm | |

| Four-sided forming minimum inner dimension | 140mm × 140mm (without back folds, excluding hinge blades) | |

| Four-sided forming minimum inner dimension | 140mm × 260mm (with fold, including hinge blade) | |

| Bending angle | 0-180° | |

| Number of axles | 15 |

※ Parameters are subject to change without prior notice.

PROCESSING EQUIPMENT

We have sophisticated processing equipment and professional manufacturing technology

OUR SERVICES

Our products are sold in more than 80 countries and regions around the world

What are the factors that affect high product parts?

Machining has been used in many ways, because the current mechanical manufacturing requirements for output have decreased, the requirements for size and shape have gradually increased, and there is a new development trend for high-quality parts.

Precautions for fine machining, industrial requirements

Fine machining is a casting process with little or no cutting, which is a good process technology in the foundry industry, and its application is widespread. The reasons for choosing meticulous machining are as follows:<br> It can use universal materials and can utilize large amounts of scrap metal and recyclable resources.

"Machining" surface treatment

Chemical polishing: A process method in which the surface of the workpiece undergoes chemical or electrochemical changes under the action of abrasives and chemical solvents, so as to achieve the purpose

Important indicators of machining and structural design

Fine machining in the production process because of the transition of the band size is small, which will make its mechanical properties, fine machining can be achieved to the extent of its mobility and the formation of bright crystals shall not prevail, the general temperature of 715 ~ 740 ℃. Meticulous mechanical processing of the production temperature, to the extent that the melt in the process of reinjection will have good fluidity, equipment in the process of selecting the casting temperature needs to be based on the process of reinjection of the distance as well as reinjection of the process of cooling and other factors to be determined.

Machining process and technology

Fine machining can be divided into upper and lower die methods, which can be completed through comprehensive processes such as planing, milling, etching, turning, and EDM. The size and pit shape of the fine machining are consistent with the edge of the product, mainly because the wax die is mainly used for industrial wax forming, so its melting point is not high and the hardness is not high when selecting

Machining production process

The role of additives in the process of fine machining will no longer be limited to helping the shell quickly build up the wet strength, but also improve the development of its investment casting quality, the surface quality of the silica sol shell is good and its high temperature. The high temperature anti-deformation ability of fine machining is good, and the product requires its precision to be a relatively good process, so we should increase the understanding of the fine casting process in practice and theory, constantly supplement its technical attempts, and enrich its practical experience.

HOT PRODUCTS

We have sophisticated processing equipment and professional manufacturing technology

MESSAGES

If you have any questions, you can leave us a message. We have professionals to reply to you. Please fill in the correct contact information!